Best Sanding & Grinding Accessories At The Moment

Grinders

Depending on the accessory and material being utilised, grinders are often used to smooth or cut hard surfaces and materials. The fundamental grinding tool consists of a motor linked to the arbour (shaft) via a female threaded fastener, along with an abrasive wheel, wire brush, or other attachment (arbor nut). A suitable wrench or spanner is required by certain manufacturers’ arbour nut configurations in order to remove and install their own uniquely created form of fastener. Both portable and stationary kinds of grinders are available, and some have a variable speed setting. Each kind of grinder may be customised with accessories for certain uses, and each manufacturer has different functions and parts.

Grinder Safety

It is crucial to consider if the accessory’s rating for revolutions per minute (r.p.m.) matches or surpasses that of the grinder when selecting accessories for grinders. A grinder attachment that is the wrong size might break or shatter, inflicting harm. Before replacing accessories on grinders, the tool should always be unplugged or the battery removed. Similar to many other rotating power tools, portable grinders have the potential for kickback, therefore users should exercise the same fundamental care as they would when using a portable power saw. To stabilise the objects being ground, tool rests or tables are provided with bench grinders. To avoid harm in the event that the grinding wheel grabs the object and pulls the operator’s hand(s) in its direction, they should be set as near to the wheel as is practical. Bench grinders must also have transparent lens shields with an adjustable impact resistance that must always be worn by the user of any grinder. Always check manufacturer instructions before using any power tool you are unfamiliar with due to the large range of grinding equipment and applications. The majority of grinders are not suitable for wet applications, despite the fact that some of these instruments are also available in special versions that may be used in the presence of water to cool the blade or stone and flush debris from the cut or material surface.

Grinder Accessories

In order to turn a grinding disc into an orbital sander, a hard rubber backing plate must typically be fastened to the grinder and the disc must be fastened to the backing plate using an adhesive or hook-and-loop system. The material being sanded should determine the disc’s sandpaper material composition (see Sandpaper Material Composition). Cotton, microfiber, and other materials often used for hand polishing objects may be utilised to make buffing wheels and bonnets for metals, plastics, quarry stone, and other surfaces. Buffing wheels are attached to the arbour of stationary grinders with the arbour nut, while bonnets are fixed to backing plates on portable grinders or buffers.

Sanders

Choosing the best sanding tool and sandpaper to use for a job, whether you’re using a power sander or sanding by hand, may be a difficult chore if you’re not aware with the capabilities of the equipment and the range of sandpapers available for different uses. Sanders may be used to strip or produce precise finishes as well as mould and shape a broad range of materials. In order to use the maximum capability of the instrument and sandpaper being used depending on the material being sanded and the finish sought, while working with electric power sanders, the speed should be set to a speed that generates the optimum cutting action. It’s crucial to delegate tasks to the tool, just as with other power equipment. Due to excessive friction or by preventing the tool from rotating or vibrating at all, applying too much pressure to the tool may slow down or dampen the machine’s activity. Some sanders (orbital or track) revolve continuously, leaving swirl or sanding lines in the materials they touch. Fewer lines and finer finishes are produced by the numerous routes used by random orbital and oscillating sanders.

Styles

The word “grit” is used to describe how coarse (rough) the material is on the sandpaper. The coarseness of sandpapers is indicated by a number; the lower the number, the coarser the grit and the rougher the finish; the higher the number, the finer the grit and the smoother the finish. Aluminum oxide, garnet, silicon, or even emery cloth may be utilised as the sandpaper’s cutting component since they are resistant to disintegration in moist environments. It is preferable to start with a coarse sandpaper when sanding objects that need a lot of effort and progress gradually to finer grits to get the desired finish.

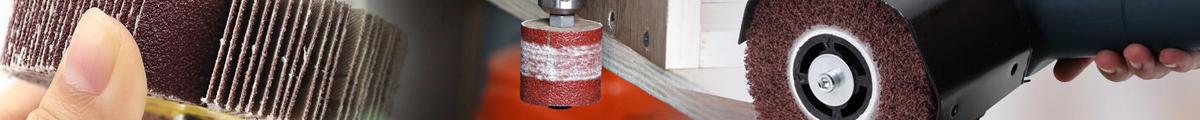

Flap Sanding Wheels on Shank

Flap sanders come in a variety of grits and sizes designed to smooth out rough cuts and remove burrs from your wood and metal surfaces, giving you flexibility and control over your finish. Flaps are uniquely crafted to fit the contours of the region that stiff sanders cannot access. These accessories may be mounted on any drill or drill press thanks to the universal 1/4 inch shank. They are perfect for hard-to-reach regions of your projects, such concaves and drilled holes, due to their cylindrical form.

Sanding Drums and Sleeves

To smooth, buff, and condition surfaces, sanding drums and sleeves may also be placed on a 1/4 inch shank and used with a drill for mobility and to reach awkward places, or they can be used with a drill press for freehand operation. They are excellent for sanding inside surfaces and deep holes, and they may be quite effective for hard-to-reach locations. Sanding drums and sleeves, with their distinctive cylindrical form, enable you to complete rounded portions of your material, such as curves, and are also excellent for removing band saw markings.