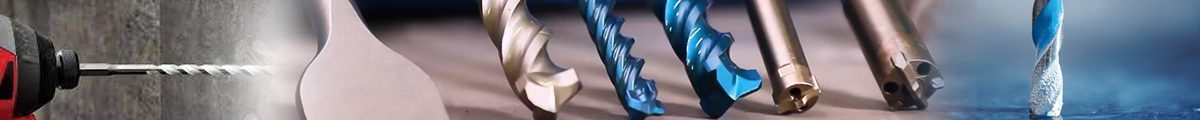

Best Multi Construction Drill Bits At The Moment

Multi Construction Drill Bits

In a variety of occupations, drills and drilling equipment are used to bore round holes. Drill is the name of the device used to create the boring hole. Drill machine refers to the device used to move the drill. Drilling is the process of creating holes with drills and drill machines. An instrument for cutting, a drill bit is used to create or expand holes in solid metal. These are used with a drill press or manual drill that has a chuck. The clamp on these drilling machines is adjusted using a key. A drill is one of the top workshop tools and is necessary for practically any job. However, you can’t use any drill unless you know which drill is best for your task. There are many different sizes available for drill bits.

Flat Drill

Slender sticks of high carbon steel are often beaten to create this sort of drill. They grind, harden, and temper their cutting edge. It is simple to create in any size or form. After they’ve been forged, they are manufactured in various sizes. They are relatively inexpensive drills. Iron hole digging is not done with it. Typically, it is used to drill holes in soft metals and carpentry projects. A 90° angle is maintained at the cutting point. This drill may be used on solid metals when conventional drills break after being appropriately hardened and heated.

Straight Fluted Drill

The flutes or grooves of a straight fluted drill run perpendicular to the drill axis. One might imagine a straight fluted drill as a cutting tool with no rakes. Since the chips do not just pop out of the hole, this sort of drill is not often used. Practically speaking, they are used while drilling brass, copper, or other softer materials. When drilling brass, the twist occurs more quickly than the feed rate, causing the drill to penetrate the metal. The use of a straight fluted drill is not difficult in any way.

Twist Drill Bit

Today, twist and thick drills are used to swiftly bore clean, precise holes of the desired size. These are often constructed from thin alloy steel rods and high-speed steel. Then, a cutting edge is formed on the bottom end, and a flute—a twisted groove that runs from top to bottom—is cut. It is known as a twist drill because of the twisted flute. Its essential components are the tang, shank, body, tip, and neck.

Centre Drill

Another name for it is a combo drill. It has cutting points on each of its extremities, and its midsection is plain. With this drill, drilling and countersinking may be done concurrently. It is used to drill the centre of a rod when lathes are turning long pieces of work from centre to centre. In the figure, it is shown.

Counter Boring Drill

This drill does counterboring when Allen screws are installed. These kinds of screws are also installed on the surface of the project like the counterscrew. It is used to widen a hole. From the top side up to the height of the screw head, a hole is drilled. The surface of the work stays comparable to the plain surface for fitting this sort of screw. The screw heads don’t interfere with how they work in any way. The hole is cut at a 60° or 82° angle from the top when countersinking, however when counterboring, the hole is created deeper and larger until it reaches the height of the screw head. The counterboring drill is often referred to as a counterboring cutter. On its bottom side, a pilot is constructed. This pilot embeds itself in the hole and facilitates accurate counterboring.

Installer Bit

These drill bits have a unique twist that is used to drill holes for the installation of cables for security and entertainment systems. These drill bits, which may be up to 18 inches long and resemble auger bits, They can be used to drill through certain masonry, wood, and plaster.

The bit’s tip has a little hole in it. You must push the wire through the hole after drilling one in the surface by inserting it into the tip’s hole. Pull it over from the other side.

Hole Saw

This kind of drill bit may be used to install door hardware or provide a pass-through for wiring. A side cut-out in the saw cylinder forces the worthless plug produced by the hole saw out of the way.

Additionally, you may use a pilot bit to steady the blade and an attachment to centre the hole. A built-in shank, as opposed to a pilot bit, is included with small hole saws. A bi-metal hole saw may be used to drill holes in both metal and wood.

Forstner Bit

This kind of drill bit is ideal if you want to drill neat, smooth holes in wood. With this bit, precise holes may be made. It features a sharp tip that aids in keeping the bit in the desired location. It doesn’t have a flute, and you have to routinely remove it to dust and chip the flute. A drill press with this kind of drill bit is necessary for a number of applications.

Auger Bit

The use of an auger drill bit may be used to create a hole in thick, dry wood. It is fairly simple to build a hole in the trees, so you don’t need to exert as much force. These feature a screw tip that both drills the hole and aids in pulling out the bit to produce a tidy hole.

Given that several of these bits have a length of up to 18 inches, you may use them on thicker wood. Its big flute, which allows dust to enter the opening, supports the channel. Some varieties allow for even greater chip removal since the centres are hollow.

Applications of Drill Bit

The drill bits are designed to create holes in a variety of materials. This uses a variety of materials, including concrete, ceramic tile, porcelain, metal, plastic, and wood. Additionally, drill bits for sheet metal, fibreglass, brick, cast iron, steel, aluminium, copper, and other materials are available.

Drill bits are made in a variety of designs depending on their diameter to help with certain jobs. Step drill bits may be used to create any surface, depending on thickness. Additionally, you may drill holes in high tensile metals by employing a drill bit made of cobalt.